This Airloc ABS Wide Spade gives great performance for speaker termination. Using the latest Airloc technology, this Airloc ABS Wide Spade is the ideal speaker termination to ensure you are getting the best out of your speaker cable.

Highlights

- 24k Gold plated

- High copper brass body

- AirlocTMcold weld system

- Accepts entire QED cable range

- Color-coded ABS barrels

Product Details

QED Profile 42 Strand

QED’s ABS gold-plated wide spades feature a high copper brass body. The wide spade is designed to connect to speaker terminals up to 10mm wide. The spades accept the entire QED cable range. ABS barrels are color-coded. Minimum cable size: 0.75 mm2. Maximum cable size: 5.5 mm2. Available in red, black, yellow, and blue.

What is AIRLOC™?

Airloc™ is a form of cold weld system that can be used to permanently attach QED Forté™ banana plugs or spade terminals to our entire range of speaker cables.

One of the main reasons for choosing a QED speaker cable is the superior d.c. resistance characteristics offered by our exclusive use of 99.999% oxygen-free copper conductors. It seems a shame then to ruin all this attention to detail by neglecting the most vulnerable area of the speaker cable chain - that of the physical interface between cable and amplifier or speaker terminals.

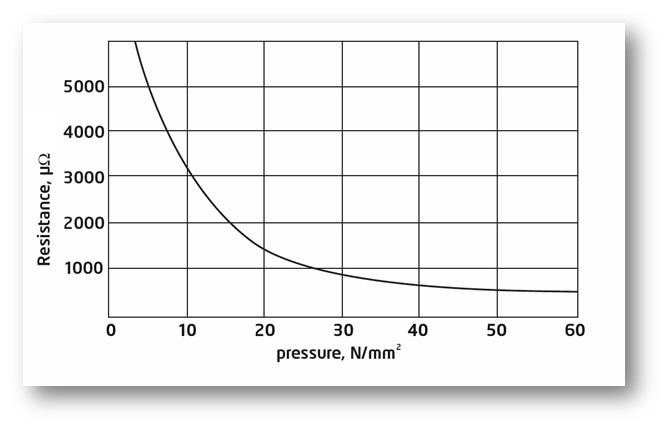

Seen under a microscope the surface of a typical copper strand is very rough and so using normal screw-type terminals - as found on binding posts or cheap banana plugs - electrical contact is only made in a relatively small number of places. Add to this a layer of oxidation - which is inevitable if copper is exposed to the air for even a short time - and the combined resistance of the cable and its termination can creep back up to levels present in a more inferior cable.

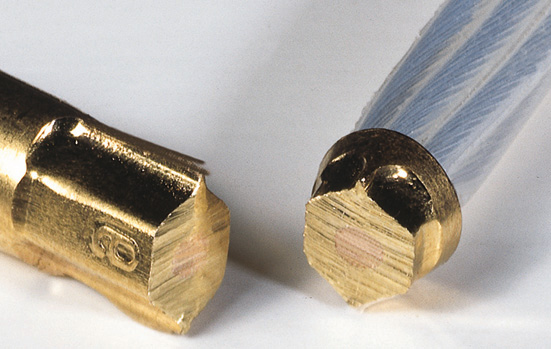

By using a cold weld crimp type termination Airloc™ plugs squash the conductors and plug them together to improve contact area and reduce resistance.

As can be seen in the graph below, by the time the full pressure has been applied the resistance of the joint has reached a minimum value.

Now, because all the air has been removed from the joint there will be no oxidization of the contact surfaces so the low resistance will remain for the lifetime of the cable. During the cold weld process, the cable and plug become one solid piece of metal.